Massimiliano Nucci (GNA): "It fills up to 80 trays per minute".

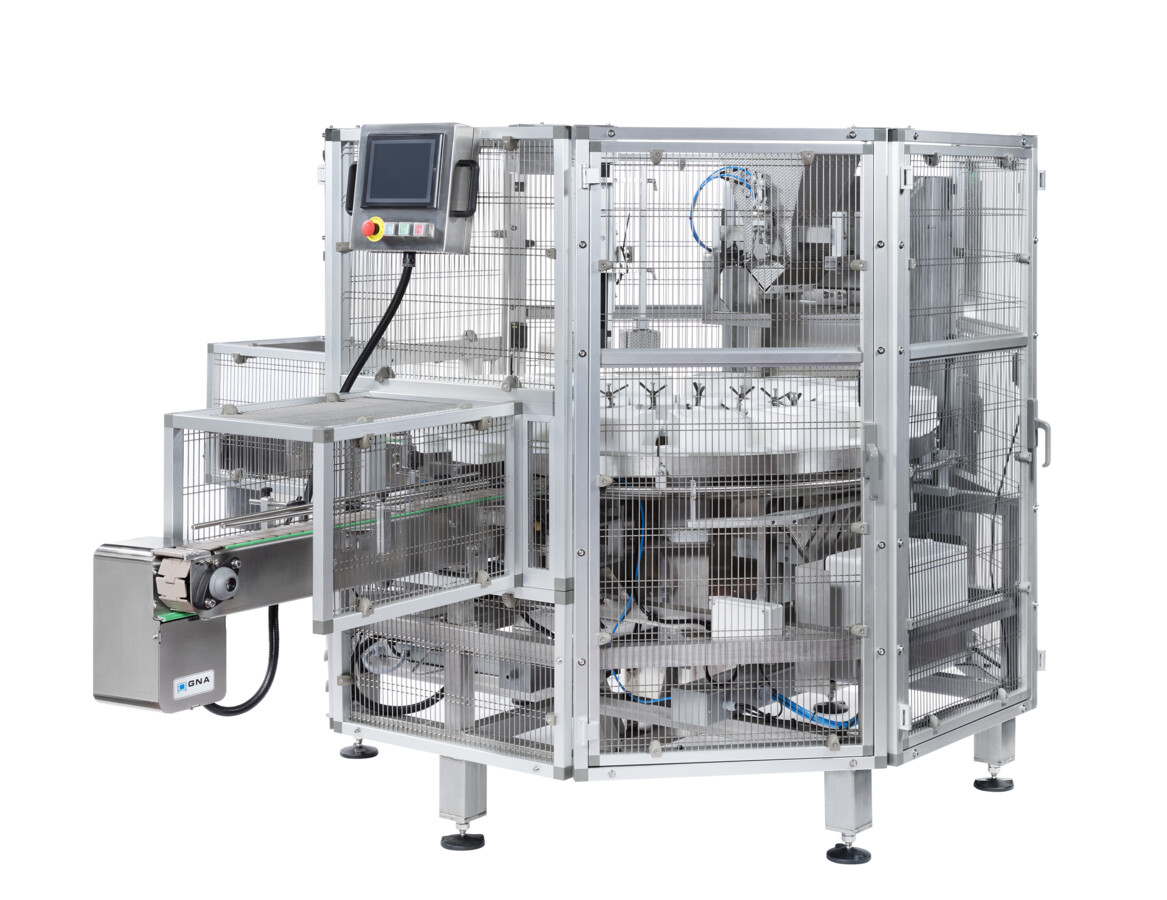

V80/S, a tray filler that is precise and efficient

The production and preservation process of packaged salads, vegetables and fruits in the fresh-cut sector consists of several stages: selection, sorting, peeling and cutting, washing, drying and sealed packaging.

Speaking of the packaging stage, precision and efficiency are the distinctive and technical features of the Tray Filler mod. V80/S launched by the Italian company GNA in 2017.

.jpg)

"The V80/S is mainly used in the fruit and vegetable and fresh-cut sectors for filling trays of various sizes and shapes - round, square, rectangular. In fact, it fills up to 80 trays per minute," says Massimiliano Nucci, Design and R&D Manager at GNA, of which the fresh-cut sector accounts for 40 percent.

"Our customers appreciate the V80/S for its versatility in the positioning of the infeed and outfeed belts, with the possibility of multiple setups according to the product flow; for the ease of format changeover; for the ease of cleaning; for the reliability of the rotation of the central table, entrusted to a very robust and powerful gear motor; for the automatic height adjustment; and for the high performance".

.jpg)

"AISI 304 stainless steel is the only material used for the frame, electrical panels and panels, guaranteeing high standards of hygiene and cleanliness," continues Nucci. "The brushless motors allow high performance in terms of speed and precision, both in terms of disc rotation and pressing."

The basic V80/S can be supplemented with various accessories as required. "The machine is built on an octagonal structure that allows total customization. For example, some customers have asked us to add an extra pressing station (normally there are two, ed.) or to create an eight-station version instead of the standard 16, mainly to reduce the space occupied in the production area," concludes Nucci. "The V80/S can also be combined with any weighing system and any packaging system, such as flowpack and heat sealing.

Source: Freshplaza.